How does an OGV+ VPSA industrial oxygen generator work?

Simultaneously the first ‘saturated’ tower will be regenerated by an extractor pump that extracts the moisture and nitrogen from the adsorption material making it ready for re-use again.

Benefits of an OGV+ VPSA industrial oxygen generator

- Lower your oxygen costs: No truck shipments of liquid oxygen required and youb can produce oxygen at the lowest possible cost.

- Only produce what you need: Produce the amount and purity oxygen that you need, any time and on-site.

- Large turndown ratio: Variable flow blowers and extractor pumps ensure a large turndown ratio and guarantee low energy consumption, even at reduced load.

- Efficient at any flow: Constant low specific energy required to produce one unit of oxygen remains.

- 100% Oil-Free technology: Oil and oxygen are a very hazardous combination. Atlas Copco therefore offers unique 100% oil-free oxygen generation technology including ISO8573-1 class 0 oil-free blower and extractor.

- No air dryer required: The OGV+ has an integral drying layer that captures all moisture and CO2 before the oxygen is concentrated.

Atlas Copco Oxygen Generators

A dependable source of industrial gas is critical in many industries and Atlas Copco On-site Oxygen Generators are a very reliable source of pure oxygen.

On-site gas generation allows you to produce oxygen anytime you need meaning you can stop relying on third-party suppliers for your oxygen gas supply and make your own with one of our gas generators.

On-site production of gas offers a wealth of advantages ranging from cost savings to continuous availability.

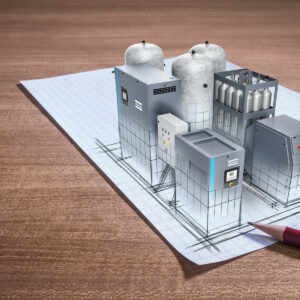

Atlas Copco oxygen generators use pressure swing adsorption (PSA) technology. The generator consists of two separate pressure vessels filled with zeolite molecular sieve (ZMS) material that separates the oxygen from the incoming air. At any time, one of these vessels produces oxygen while the other is “regenerating” its saturated ZMS.

BRE UK is very experienced in helping clients determine if on site oxygen generation is possible, and how much cost savings you could achieve by switching to on-site oxygen generation.

How is On-Site Oxygen Generation more Cost Effective?

Oxygen Generators will Reduce your Energy Usage

Atlas Copco's Oxygen Generators use a Variable Cycle Saver. Most users don’t need to utilise the maximum capacity of their oxygen generator all the time. Atlas Copco's in-house developed Variable Cycle Saver (VCS) eliminates energy waste during lower demand and in colder temperatures, giving you up to 70% additional energy savings.

Oxygen Generators will Reduce Feed Air Requirements

Thanks to its feed air efficiency and best-in-class ZMS utilisation, Atlas Copco Oxygen Generators can deliver double-digit reductions in the total cost per unit of oxygen with up to 30% less feed air required than a traditional gas generator.

Contact BRE UK for a Oxygen Generation Quote

Contact BRE and our team will prepare a tailored quotation for you that is specific to your Oxygen use requirements and a recommendation of a suitable Oxygen generation system from Atlas Copco. We’ll be able to project your annual running costs, and compare them to the proposed system so that you can also measure your expected return on investment.

A state of the art Atlas Copco Oxygen Generation System will likely deliver a very fast return on initial investment even after you’ve considered initial purchase price, electrical running costs, maintenance costs and compared this to your existing costs for buying in nitrogen in bottle format.

As a guide, we generally see ROIs of less than 2 years for Oxygen Generators.

Why Choose BRE UK For Your on Site Oxygen Generation in Scotland

When compared with the delivery of oxygen bottles or bulk tank top ups of oxygen gas, on site generation can be delivered very cost effectively by using excess capacity from your existing compressed air supply, or installing a stand-alone oxygen generation system.

BRE UK is very experienced in helping clients determine if on site oxygen generation is possible, and how much cost savings you could achieve by switching to on-site oxygen generation.

Feasibility Study

Established in 1985 and based in Dundee, BRE prides itself on compressed air expertise, helping businesses improve their operations, reduce costs and achieve energy savings right across Scotland including in Aberdeen, Edinburgh, Glasgow, and Fife.

As the longest serving Premier Distributor of the Atlas Copco Industrial Air Range of Equipment in Scotland, BRE’s expert team will help you to determine;

- If an Oxygen Generator will achieve your required levels of gas purity

- If you have a sufficient compressed air supply to generate Oxygen

- Your predicted costs for bottles or top ups over the course of 12 months

- Potential cost savings you would achieve through on-site Oxygen generation

- How quickly generating your own Oxygen will yield a return on your up-front investment

Finance Options

As the longest serving Premier Distributor of the Atlas Copco Industrial Air Range of Equipment in Scotland, BRE can offer you a range of professional financing options that build in the flexibility you need to fund your capital investment. Purchasing an Atlas Copco Oxygen Generator is a long-term investment and we have a range of finance options to help you finance your purchase over 3 - 60 month period.

Instead of waiting for a return on your investment, many companies can make savings immediately with your tailored quotation easily demonstrate that your monthly payments may be lower than your usual monthly outgoings.

Lowest Total Cost of Ownership

Once you have agreed to proceed, BRE will take care of the installation of your new oxygen generator at your premises in Scotland and you can relax and enjoy the savings.

Your biggest ongoing cost will be in the electrical energy required to generate the compressed air supply and Atlas Copco Oxygen Generators have some of the lowest air to Oxygen ratios available on the market. As a result, an Atlas Copco Oxygen generator will help ensure the lowest total cost of ownership compared to other market alternatives.