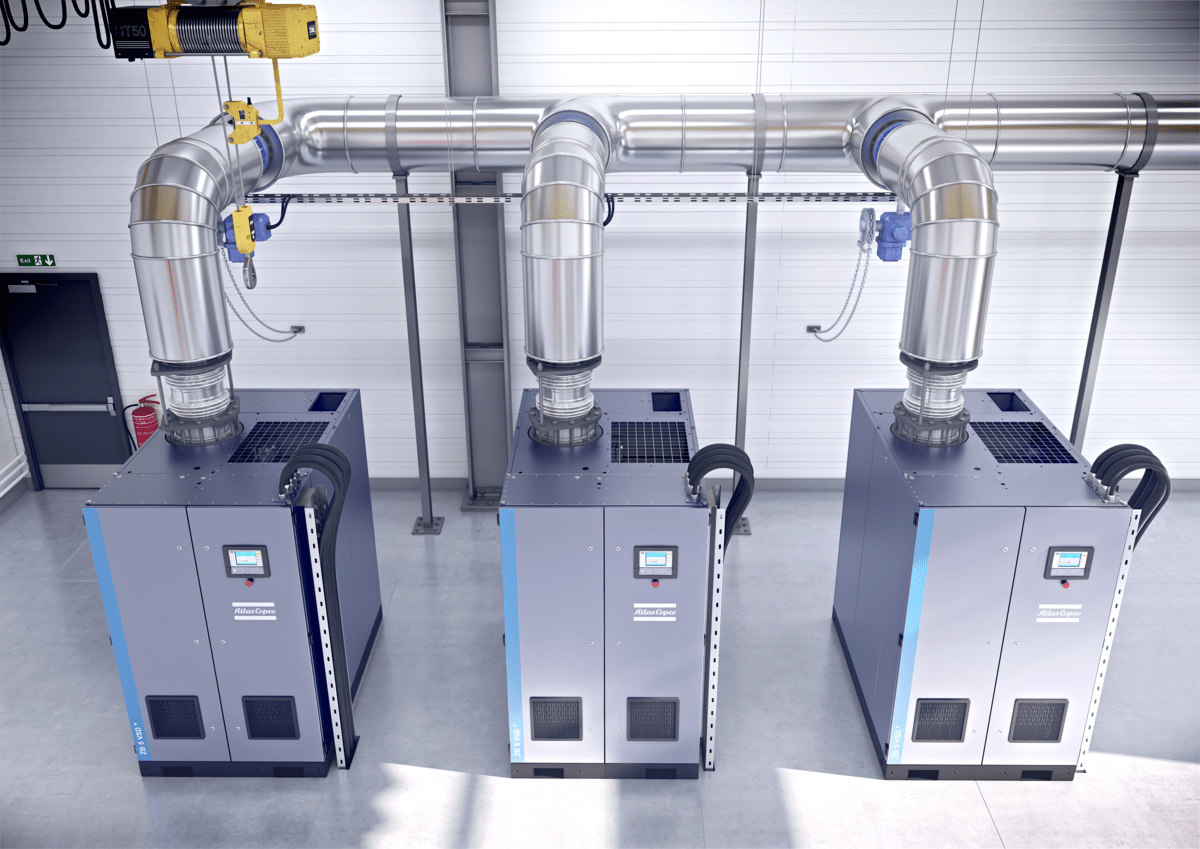

Atlas Copco Turbo Blowers

Atlas Copco Turbo Blowers – What makes our ZB 5-6 VSD+ so suited for a variety of low pressure applications?

All of the components of our new ZB turbo blowers series are selected with the same goal in mind. Successul in reliable, highly efficient and continuous operation in all kind of applications including wastewater treatment, pneumatic conveying and flue gas desulphurization. Moreover, our ZB 5-6 VSD+ turbo blowers are Class Zero certified. Ultimately no oil is added during the compression process providing you with 100% oil-free compressed air when the atmosphere doesn’t contain any oil particles. , Safeguarding the quality of your end product is paramount ultimately making the new ZB series ideal for application in the food and beverage industry .

Energy Costs

Our new generation of oil-free turbo blowers helps you to reduce your electricity cost by limiting pressure drops and temperature rise to a minimal. The minimal rise in temperature is achieved by maintaining the air intake temperature to a minimum. This induces as little resistance as possible to the air passing through each component of the process air path, resulting in an equal temperature of the ambient air and the intake air. Thanks to decades of innovation of our rotating equipment design and the development of the most advanced calculators, we are able to offer you an optimal air flow. Resulting in helping you to save even more on energy costs.

Increased Lifetime

Minimized temperature also means maximized lifetime of our critical components such as the Permanent Magnet Motors and drives. These are cooled by using an internal water circuit so that they operate at their best efficiency, regardless of the ambient conditions.

With our newest generation of blowers, Atlas Copco is launching a technology that doesn’t require any power bank in case of power failure. The ZB 5-6 VSD+ the most straight forward magnetic bearing blower ever made.

Reviews

There are no reviews yet.